| ConsultationOur Consultation Slogan Academy Vs Practical Solution |

| ConsultationOur Consultation Slogan Academy Vs Practical Solution |

Our engineering consultation Serve all engineering business to ensure the efficiency and production quality as well as qualifying those companies for the modern management systems.

Technology is the driving force of progress to ensure a more sustainable future for our customers, their assets and society.

As a global technology company, we deliver comprehensive asset integrity management solutions for all areas of the integrity process chain of industrial assets.

Our team operates world-wide – empowering our customers to make the best decisions for the safety, lifetime and performance of their critical industrial assets.

With a portfolio of highly advanced proprietary diagnostic technologies, a vast and unique data set, and industry-leading software solutions combined with integrity engineering consulting services.

We provide distinctive capabilities to deliver a comprehensive understanding of asset safety, lifetime, and performance.

Our product and service portfolio offers inspection and non-destructive testing solutions, integrity assessments, engineering consultancy services, software solutions as well as cleaning services and products for various assets including pipelines, storage tanks and processing facilities.

| Asset Integrity [AIM] The goal of asset management is to effectively manage corporate assets to gain maximum value, profitability and returns while safeguarding personnel, the community, and the environment. A true Asset Integrity Management program incorporates design, maintenance, inspection, process, operations, and management concepts, since all these disciplines impact the integrity of infrastructure and equipment.

Petroproject provides specialists and engineering support in all areas of Asset Integrity Management, including design, process safety, mechanical integrity, inspection and maintenance, operational and process support, corrosion, metallurgy, and risk analysis to provide you with Total Quality Assurance.

Our experts have in-depth knowledge of oil, gas, petrochemical, power, renewable energy, civil and infrastructure fields, providing Asset Integrity Management solutions clients need to achieve productivity gains, while meeting safety and environmental concerns.

Asset Integrity Management [AIM] Solutions include: Aware Asset Performance Management [APM] Software Risk-Based Inspection [RBI] Wind Energy Services Forensic Engineering and Failure Analysis Services Offshore Hazard and Risk Assessment Services 3D Laser Scanning Technical Inspections Pipe Aware - Tracking Pipe Inspection Data Predictive Analytics for the Energy Industry Dimensional Control Smart Asset Optimization Surveying and Mapping Energy Services Non-Destructive Testing [NDT] Services High Energy Piping Program |

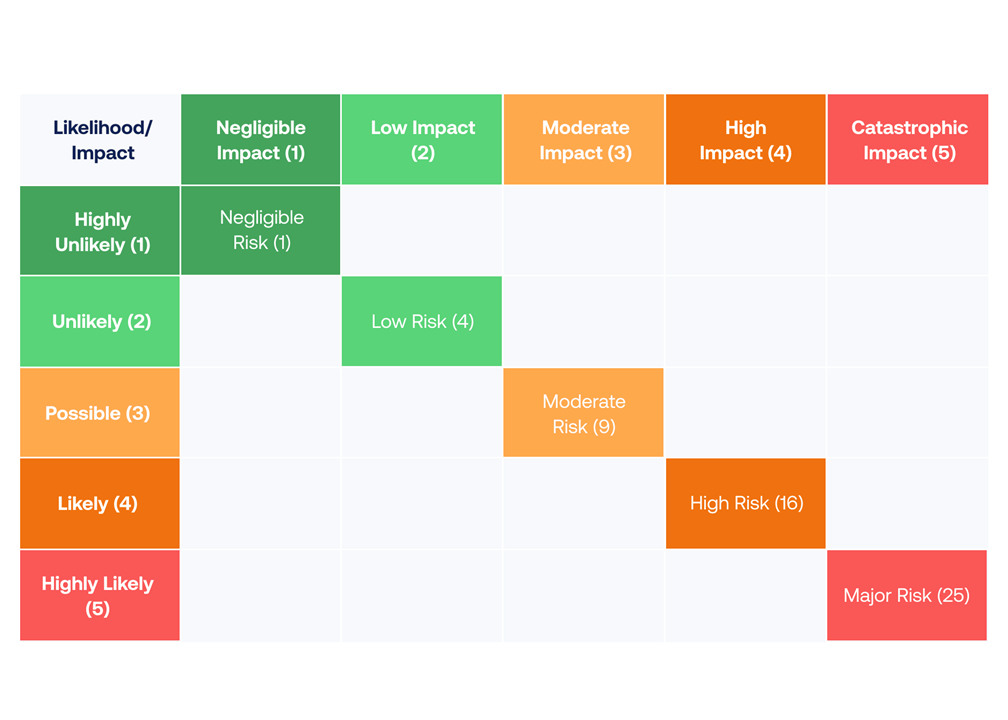

Risk Based Inspection [RBI] Petroproject methodology in RBI, [how to control corrosion risk vs production economics under the full integration level with asset management [AIM]. Risk-Based Inspection [RBI] is an analysis methodology and process that, as opposed to condition-based inspection, requires qualitative or quantitative assessment of the probability of failure [PoF] and the consequence of failure [CoF] associated with each equipment item, piping circuits included, in a particular process unit. A properly implemented RBI program categorizes individual pieces of equipment by their risks and prioritizes inspection efforts based on this categorization.

Why use RBI? RBI is used to identify and understand risk, risk drivers, and where equipment is in its lifecycle. RBI can indicate whether inspection is needed. RBI can be used to prioritize inspection-related activities, usually by means of nondestructive testing [NDT], to reduce the uncertainties around the true damage state of the equipment and the dynamics leading to such. The resulting inspection plan may outline the type and scheduling of inspection for an asset.

Supported Codes and Standards International engineering standards and practices that relate to risk-based inspection include, but are not limited to, API RP 580 and 581, ASME PCC-3, and RIMAP. API RP 580 sets out the minimum guidelines for implementing an effective, credible RBI program. API RP 581 details the procedures and methodology of RBI.

|  |

| Safety Integrated Level [SIL] Petroproject is providing the Safety Integrity Level [SIL] Study that required to assess the distinct level for specifying the security integrity needs of the security instrumented functions [SIF] to be allotted to the security instrumented systems. Layer of Protection Analysis [LOPA] methodology is followed by the accounts of the protective layers to stop forestall and to mitigate dangerous events with inherently safe design conception, to prevent the incidence / mitigate the results from such unsafe event.

Technical Challenge: There is an increasing dependence on Safety Instrumented Systems [SIS] to achieve tolerable risk levels within the method sector. Additionally, there’s an increase in ought to justify that the chance levels that are achieved are tolerable.

SIFs are one amongst the layers of protection that are designed into method plants mitigate the incidence of major hazard scenarios; this suggests that the failure or absence of a SIF will increase the likelihood of an unsafe scenario occurring and escalating into a significant accident. It’s then necessary to estimate the chance of the Sif failing to act on a requirement, for the users to determine if the target risk levels of their organization or country are being achieved.

Petroproject Approach / Methodology in conducting SIL SIL assessment could be a risk-based approach to spot the desired safety integrity levels [SIL] for safety instrumented functions [SIFs] in accordance with IEC 61508 / 61511 or ANSI/ISA S84.01.

The SIL assessment is performed by a multidisciplinary team led by a SIL facilitator. Determination of the SIL of a SIF may be achieved using completely different qualitative and quantitative approaches.

Risk Graphs – qualitative technique, projected in IEC 61508 Layers of protection analysis [LOPA] – various qualitative methodology, wide employed in the method trade Fault tree analysis [FTA] / Event tree analysis [ETA] – quantitative strategies Generally, a mixture of strategies is used. As an example, performing arts an initial qualitative assessment for all safety functions (“screening process”) and performing a detailed quantitative assessment for the higher criticality or less well understood functions.

Supported International Standards: IEC 61508 – 2010 Edition – Functional Safety of Electrical / Electronics / Programmable Electronic safety related systems IEC 61511 – 2004 Edition – Functional Safety: Safety Instrumented Systems for the Process Industry Sector – all 3 parts |

HAZOP and PHA PHA by Petroproject Process hazard analysis [PHA] examines a process to identify potential hazards and assess the associated risks. PHA evaluates the process from different angles, considering various scenarios and possible deviations. It aims to identify and prioritize hazards, determine risk levels, and recommend appropriate control measures to effectively manage and mitigate those risks.

Petroproject Methodology in conducting PHA As per OSHO, there are different ways to conduct hazard analysis processes, such as, Layer of Protection Analysis [LOPA] Hazard and Operability Study [HAZOP] Failure Modes and Effects Analysis [FMEA] What-If Analysis Fault Tree Analysis [FTA] Bow Tie Analysis Hazard Identification [HAZID]

HAZOP by Petroproject HAZOP [hazard and operability study] is one of the methods for performing PHA; it is a systematic and structured technique used to identify potential hazards and deviations from the intended design of a process.

HAZOP is working on the theory that deviations from design or operating intentions cause risk events. To identify such deviations, a set of “guide words” is used as a systematic list of deviation perspectives.

It focuses on analyzing process systems, identifying potential causes of deviations, and proposing preventive or mitigative measures. HAZOP studies are typically conducted during a process’s design or modification stage to ensure safety considerations are integrated from the outset.

Petroproject Methodology in conducting HAZOP Identifying Scope & Information Making Nodes Forming Guidewords Assembling HAZOP Team HAZOP Review |  |

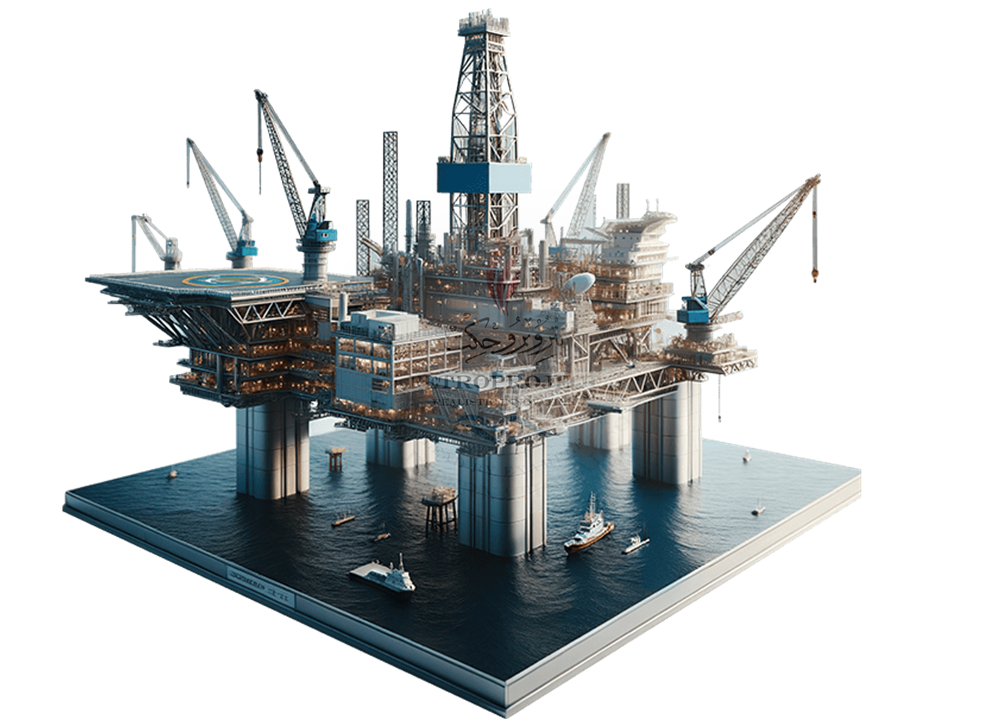

| Rig Inspection Petroproject has qualified and certified teams with more than 20 years’ experience in the rig inspection field and it is the one of best established and most experienced inspection companies in this area.

Integration Acceptance Testing. Experience that Petroproject developed in Rig Inspections helped us to develop and adopt the Integration Acceptance Test [IAT] or sometime known as SIT [Simulation Integration Testing].

Rig Inspections will be conducted using the Petroproject Acceptance Guidelines Program, which includes testing of all equipment and systems to verify their condition and performance.

Petroproject has developed an inspection program that deals with only “Operation and Safety-Critical” items. This includes but is not limited to. Intrusive inspections of the internal parts of specific equipment including critical measurements and clearance to ensure equipment is running within recommended tolerances. Function testing, pressure testing, load testing and insulation resistance checks for all critical equipment on the drilling unit, as required. Verification that the proper safety devices are installed correctly, testing that these correctly function and are correctly calibrated to prevent equipment damage and accidents. Verification that the rig equipment complies with API standards, the equipment manufacturer’s specifications and recommendations and good engineering practices. Verification that the rig is following the contractual requirements as provided by the client.

All types of Rig Inspections Conducted by Petroproject, but not limited. Pre-hire Inspections Pre-selection Inspections Periodical Conditional Inspections Well Control / BOP Inspections Specialized Equipment Inspections Accident, breakdown Inspections Crew Competency Reviews HSE Inspections |