Pressure Vessel SystemsMade by Petroprojectin accordance with international Codes and Standard |

Pressure Vessel SystemsMade by Petroprojectin accordance with international Codes and Standard |

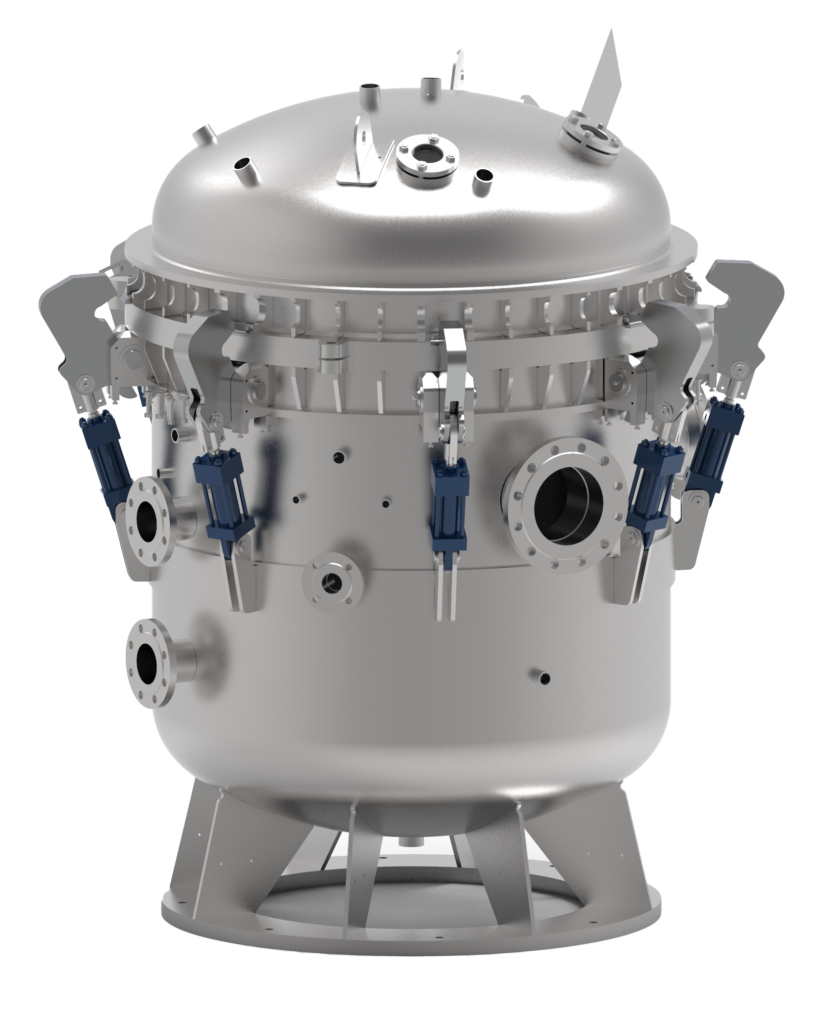

Pressure vessel fabrication is a meticulous process encompassing precise cutting, molding, welding, and assembling of metals for creating vessels designed to contain gases or liquids at different pressures.

In simpler terms, it involves the construction of specialized containers, ensuring they are built with accuracy to hold substances under varying pressure conditions safely.

Petroproject offers many types of pressure vessels which serve many industries like Oil & Gas, Refinery and Petrochemicals.

Oi l& Gas Separation Systems Two Phases and Three Phases | Reactors Systems Single-Product and Multi-Products | Distillation Towers Oil Refinery and Petrochemicals Industries | Pressurizing Tanks Which Serve Transportation and Process |

The Sequence of Fabrication of Pressure Vessels

Pressure vessel fabrication is a meticulous process involving precise cutting, molding, welding, and assembling of metals to create containers for gases or liquids under different pressures. Before starting, crucial design steps are essential:

Design Concept When concepting the pressure vessel design, engineers must clearly define the project scope and technical specifications. Specify the vessel’s shape, size, and dimensions. Fabricators choose materials based on the intended purpose.

Stress & Strain Analysis Perform mechanical calculations to determine the strength of the chosen materials for fabrication.

Fabrication Drawings Create detailed drawings specifying material parts, manufacturing standards, viewing sections, and welding/bolting information. These drawings guide the flawless execution of the fabrication process.

Material Verification The materials used in fabrication include plates, pipes, forgings, structural shapes, welding rods, or wire. These components are molded and forged according to vessel specifications, followed by machining if necessary. The welded parts are assembled, undergo cooling and sandblasting, and finally, primer and paint are applied |  | The Steps in The Manufacturing of Pressure Vessels

1.Raw Material Preparation Material Selection Choose appropriate materials based on requirements Material Inspection Ensure materials meet quality standards Material Cutting Cut materials into manageable pieces

2. Scribing Marking Guidelines Mark guidelines for cutting Inspection of Marks Ensure accurate markings for precision Verification Double-check markings before cutting

3. Blanking Cutting According to Marks Cut materials along marked guidelines Quality Inspection Inspect cut pieces for accuracy and consistency Waste Management Properly manages and dispose of excess material

4. Bending Shaping the Pieces Bend materials into desired shapes Measurement Check Ensure dimensions align with specifications Quality Assurance Inspect bends for any deformities or flaws

5. Forming Giving Final Shape Form the pieces into the intended structure Precision Check Verify that the final form meets standards Consistency Inspection Ensure uniformity across all components

6. Edge Processing Smoothing Edges Refine edges for safety and aesthetic purposes Deburring Remove any burrs or sharp edges Quality Check Inspect edges to meet quality standards

7. Assembly Fitting Components Together Assemble various parts into the vessel Alignment Check Ensure proper alignment of assembled parts Pre-Welding Inspection Inspect assembly before welding begins

8. Welding Secure Welding Weld components securely according to standards Inspection During Welding Monitor welding process for any irregularities Post-Welding Inspection Inspect welded joints for quality and strength

9. Inspection Visual Inspection Visually inspect the entire vessel for any issues Non-Destructive Testing Conduct Tests without affecting the vessel’s integrity Dimensional Inspection Verify vessel dimensions meet specifications

10. Additional Steps (if required) Testing Perform necessary tests for pressure and integrity Finishing Touches Apply protective coatings or finishes as required Final Inspection Conduct a thorough final inspection before delivery |