| Sodium Hypochlorite IndustryPetroproject EPC Projects Intergrated Industrial System |

Brief introduction of Petroproject production system

Sodium hypochlorite, commonly known as bleach, is most frequently used as a disinfecting agent. It is broad-spectrum disinfectant that is effective for the disinfection of viruses, bacteria, fungi, and mycobacterium.

Petroproject Sodium Hypochlorite Generation System is Cover the complete chemical Generation and Electrochemical Generation

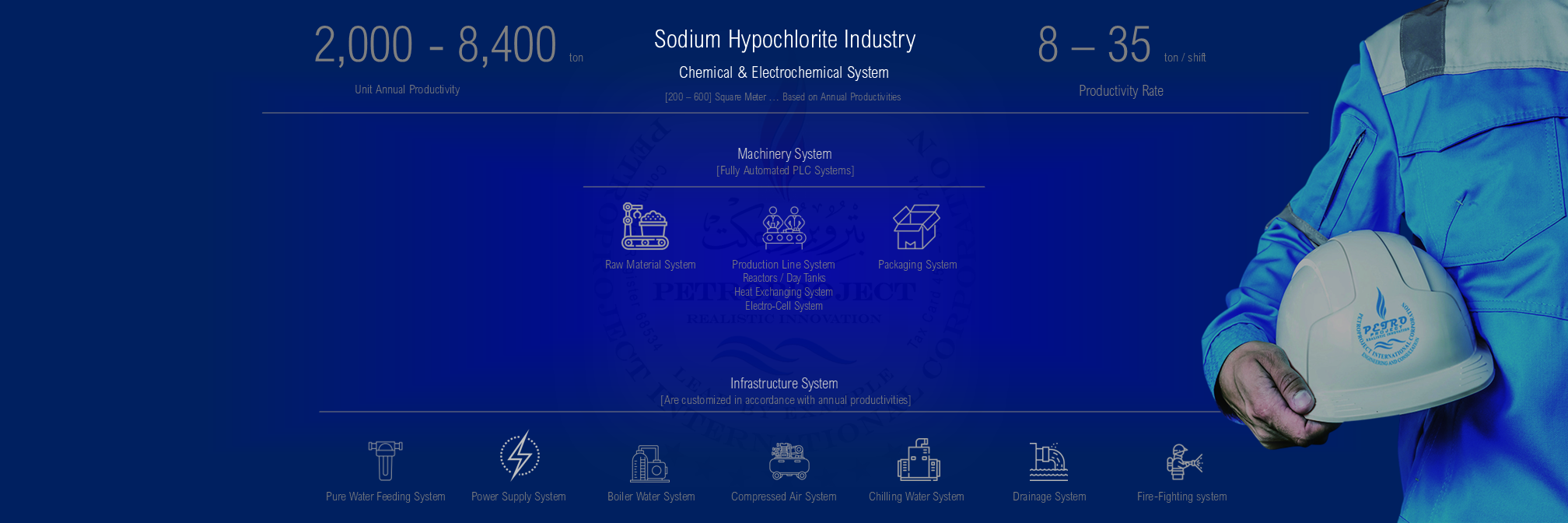

| Reactors - Day TankSodium Hypochlorite Reactor / Storage Tanks are manufactured from CPVC, HDPE, XLPE, and FRP materials at 1.9 specific gravity. Secondary containment is required. Bleach is best stored out of direct sunlight, at temperatures below 60°F, filtered and diluted with pH kept above 10. The reactor tank capacities range from 10,000 to 26,000 Liters. The reactor tank is designed for internal pressure up to 10 Bar with complete operated nozzles. Which serve the automatic operations. The reactor tank is also designed for generations of sodium hypochlorite by Chemical and Electrochemical reactions.

Commonly known as Bleach, Hypo, NaOCl, Sodium Oxychloride, Used primarily for disinfecting and whitening Federal guidelines outline correct handling and storage requirements |

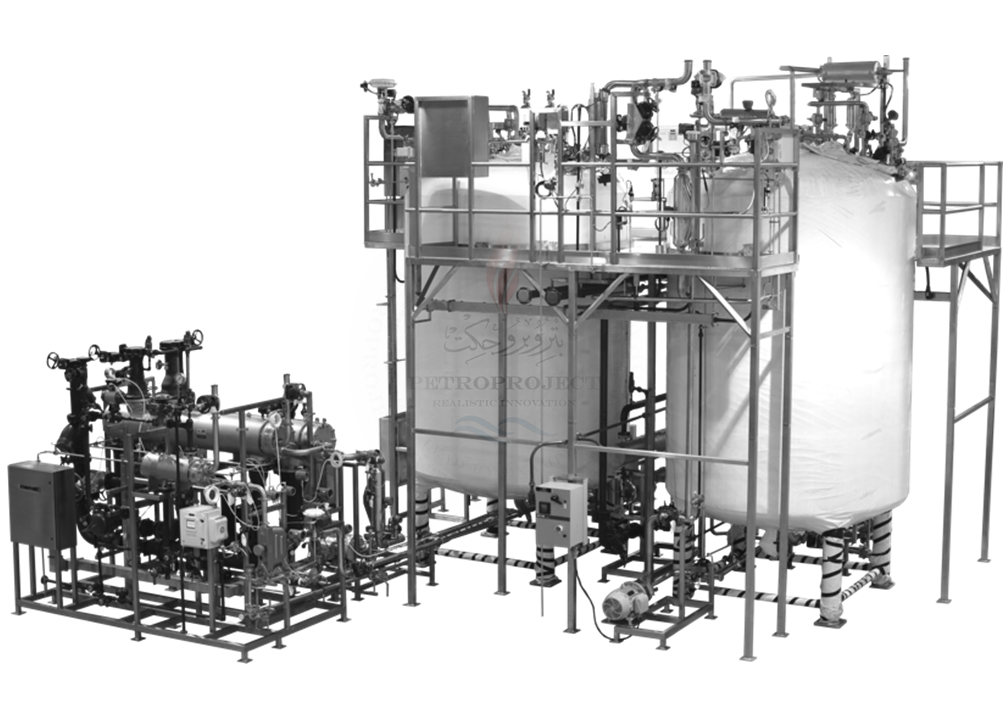

Titanium Heat Exchanging SystemShell & tube heat exchangers made from titanium alloys [TA2 or another grade] are very special for chemical processing plants, chlorate manufacturing facility, sulfur recovery units, hydrocarbon processing facilities, desalination processes, power generation and many other applications, where heat exchangers shall work under acidic and/or high-temperature conditions.

Materials are selected as per ASTM or GB standards and welded under special working environment with constant temperature control and special automatic welding machines. Manufacturing of this shell & tube heat exchanger is conducted in special-designed workshop with consideration to the temperature, when inadequate handling may cause unpleasant chemical reaction during welding.

Titanium alloys are metals, which have the composition of titanium [Ti] and other chemicals, such as carbon [C], iron [Fe], nitrogen [N], Oxygen [O], and hydrogen [H], defined in many grades of local producer’s standards.

Special properties of titanium alloy allow the use of materials and products, which are made from it, use in extreme temperatures and hostile working medium. It is praised for high corrosion resistance, high tensile strength and toughness. Titanium can work 450-500 C° for long period of time. Titanium resists corrosions to alkali, chloride, chlorinated organic substances, sulfuric acid, nitric acid.

For shell & tube heat exchangers, titanium alloys pipes and plates are used for the chemical processing plants, gas processing plants cryogenic vessels and other technologies, which require high performance from the material of the equipment.

Standards, such as ASME SB338, ASTM B338, ASTM B337, ASTM B861, ASTM B862, GB/T3624-2010, GB/T3625-2007, set and regulate the grades of the titanium alloys, and its production. Pipe diameters may vary from 6 mm up to 500 mm. Thickness of the pipes are made from 0.2 mm up to 100 mm. Material grades may differ depending on the application and requirements to the equipment, where materials are used.

Life Cycle Benefits of Titanium Heat Exchangers Titanium Heat Exchangers are highly cost-effective over the entire life cycle of the equipment. Properly maintained, Titanium Heat Exchangers can operate for decades, making them a very economic choice. Titanium Heat Exchangers can: Provide an extended service life compared to other materials of construction Eliminate expensive downtime due to equipment failure Do away with requirement for spare parts inventory Provide superior corrosion resistance Deliver high heat transfer efficiency Accommodate high steam pressure to reduce required surface area Eliminate breakage during handling, installation and operation due to fully welded metal construction

Codes & standards Tubular Exchanger Manufacturer Association (TEMA) ASME SB338. ASME Section VIII, Division 1 ASTM B338, B337, B861, B862, ASME Section I GB/T3624-2010, 3625-2007 |  |

Electrochemical Sodium Hypochlorite Generator Electrolyzing and Membrane cell Sodium Hypochlorite Generator works on electro chlorination chemical process which uses water, common salt and electricity to produce Sodium Hypochlorite [NaOCl].The brine solution [or sea water] is made to flow through an electrolyzed cell, where direct current is passed which leads to Electrolysis.This produces Sodium Hypochlorite instantaneously which is a strong disinfectant.This is then dosed in water in the required concentration to disinfect water, or to prevent Algae Formation and Bio Fouling.

Operating Principle: In the Electrolyze, the current is passed through the anode and cathode in the salt solution. which is a good conductor of electricity, thus electrolyzing the sodium chloride solution. This results in chlorine [Cl2] gas being produced at the anode, while sodium hydroxide [NaOH] and hydrogen [H2] gas is produced at the cathode.The reactions that take place in the electrolytic cell are:Chlorine further reacts with hydroxide to form sodium hypochlorite [NaOCl]. This reaction can be simplified in the following manner:The solution generated has a pH value between 8 and 8.5, and equivalent chlorine concentration up to 12.5 g/l. It has a very long shelf life which makes it suitable for storage.After dosing the solution into the water flow, no pH value correction is necessary, as is often required in sodium hypochlorite produced by the membrane method. The sodium hypochlorite solution reacts in a balanced reaction, resulting in hypochlorous acid:

A Membrane Cell: The membrane is made from a polymer which only allows positive ions to pass through it. That means that the only the sodium ions from the sodium chloride solution can pass through the membrane - and not the chloride ions. |

Automatic Filling Machine | Automatic Capping Machine | Automatic Labeling Machine | Automatic Cartooning System Machines |

Complete and independent machine, designed for the execution of filling processes at adjustable speed with a wide range of products gel, liquids, creams. Machine equipped with hopper loading system, automatic equipped with minimum and maximum level with transfer pump.

Fully automatic filler equipped with bottle inlet and outlet sensors, loading arm movement management with pneumatic motors, head immersion time management in case of foamy products

Dosing group managed by magnetic pump Adjustable operating air pressure Pneumatic motors which, thanks to the lower mechanical resistance, eliminate the formation of sparks and reduce the need for maintenance Cylinder filling chambers with Teflon piston EPDM gasket [Viton on request] Possibility of adjusting the filling speed according to the product Hopper with lid that can be opened for inspection or maintenance | Complete and independent machine, designed for the execution of capping processes at adjustable speed with a universal range of capping: Triggers, Dosers, Screw.

The machine can be equipped with a trigger loading system, dosers and automatic caps. Automatic capping machine equipped with bottle inlet and outlet sensors, cap screwing by no. 4 variable hardness rubber wheels [on request]

Capping unit adjustable in width and height according to the cap Air / electricity operation Adjustable operating air pressure Complete Screwing system | Complete and independent machine, designed for round bottles or other common cylindrical products. Such as cylindrical plastic bottles, glass bottles, metal bottles. It is mainly used for labeling round or round containers in food and beverage, and personal care products.

Equipment production efficiency: single shrink label feeding plate, microcomputer control, automatic detection, positioning, fast label change, labor-saving, accurate cutting position Suitable for all kinds of bottle. Touch screen user-friendly operation ... Sensors, servo motors, frequency converters and other well-known brands. Bottle type Round and square

| Complete and independent system, including three automatic machines starting from adjusting the bottles till producing final box with complete tapping.

The System Include Carton forming machine Bottle positioning inside cartons machine Machine for box closing] |

|  |  |  |

The global experience of scientific search for alternatives disinfectants to liquid chlorine has designated, and then practically confirmed the prospects of using low-concentration electrolytic sodium hypochlorite for water disinfection, which is obtained by electrolysis of artificially prepared solutions of sodium chloride or natural mineral chloride waters in diaphragm less electrolyzes.

In case of using an artificial electrolyte, the main costs to produce NaOCl are formed by costs of electricity, sodium chloride and water.

To obtain 1 kg of active chlorine modern diaphragm less electrolyzes consume an average of 4.5-5.5 kWh of electricity and 4.5-6 kg of sodium chloride.

Since sodium chloride is the main raw material for production of electrolytic sodium hypochlorite, the cost for its purchase, delivery and storage, depending on its grade, is up to 40% of the cost for the finished product.

Therefore, one of the most promising and less expensive methods of chemical-biocidal water treatment is the use of NaOCl obtained by electrolysis of chloride-containing solutions of natural origin [water from seas and oceans, underground brines, salt lakes, etc.] or process wastewater from ion exchange units [Na-cation exchange, Cl-anion exchange], electrodialysis, reverse osmosis, nanofiltration, etc