| Petroproject Manufacturing WorkshopOur Manufacturing Workshop Slogan True Life-Time Vs True Quality |

| Petroproject Manufacturing WorkshopOur Manufacturing Workshop Slogan True Life-Time Vs True Quality |

Our extensive experience in the field of industrial projects is the main motivation for establishing and developing Petroproject workshop.

We always strive to control the implementation time of the works as much as possible.

“Really We Succeeded and Deliverd”

Petroproject workshop always provides its clients with full readiness to manage and implement any work requested by clients

We control the execution time rates in a way that satisfies our clients while achieving standard quality rates

Our manufacturing strategy is very integrated and has a distinctive character

Safety [Our First Choice]

A series of explorations, a testing of ideas. It can be simply a series of sketches, or it can go into considerable depth, including design illustrations, annotative plans, sections and 3D models of a conceptual approach. | Quality [Our Mandatory]

We present and visualize our designs in various media’s whether its 3D imagery, Walkthroughs or 2D Renders. So, we can translate our imagination into solid materials | Time [Calculated Not Determined-This Our Logic]

At this stage, the architectural design of the project is developed and defined in detail. Detailed quantities and cost information for the overall appearance, structure, services, finishes, and landscape is generated. | Cost [Competitive and Realistic]

Construction of the project and Supervision to ensure that the design is implemented and delivered according to its specifications and the designer vision. |

| Petroproject Lifting Equipment Every workshop knows it needs strength and reliability in lifting activities. So, Petroproject focuses on the heavy-duty lifting equipment that has high level of safety, thus, we built our lifting system in accordance with international codes and standards that make working on client’s products safer and faster.

So, we’ve put together this essential list of the most important secondary lifting tools that no workshop should be without.

Overhead Crane Designed according to international standards DIN (Germany), FEM (Europe), ISO (International). Optimized design, light weight, low wheel pressure, low height. Intelligent security monitoring. Lifting capacity: 20 Ton Span: 12 mt, and Lifting height: up to 9 mt Working duty: A5 and Ingress Protection: grade H IP55

Access Steps May be not seem the most exciting piece of kit in workshop – but a set of mobile access steps is essential for the safety of anyone who needs to work at a height.

So, Petroproject set of steps with: A strong and robust frame – but one that’s relatively light for easy repositioning A handrail and an integral anti-ascent bar And an integral brake system – to hold the steps in place when you’re using them. Our standard mobile Access Steps come with a platform height of 4.0 mt, with extra sizes available on request.

Transmission Jacks When you’re dealing with heavy Equipment, even their individual parts can be too much to handle.

Thus, Petroproject set of jacks provide high efficiency of lifting through a two-way tilt for precise positioning, infinite adjustability in length and width, and a full range of adaptor plates for some of the most popular equipment, Our transmission Jacks, includes: [Bottle Jacks - Support Stands - Trolley Jacks - Pit Jacks]

|

CNC Milling and Lathing EquipmentPetroproject CNC Milling and Lathing Mahine set have many advantages are:

High Productivity The industries that are using lathe machines can be sure that these produce high quality products with top-notch accuracy, especially the CNC lathe machines. As a result, productivity will increase.

High Speed The machine in the lathe can produce many products in lesser time, especially with the use of CNC lathe and automatic lathe, because of its high-speed production.

Time and Money Saves Due to the advantages mentioned above, using a lathe machine saves a lot of time. Aside from this, it also saves money because there is no need to have many operators or turners which will result in lesser machining and labor cost.

|  |

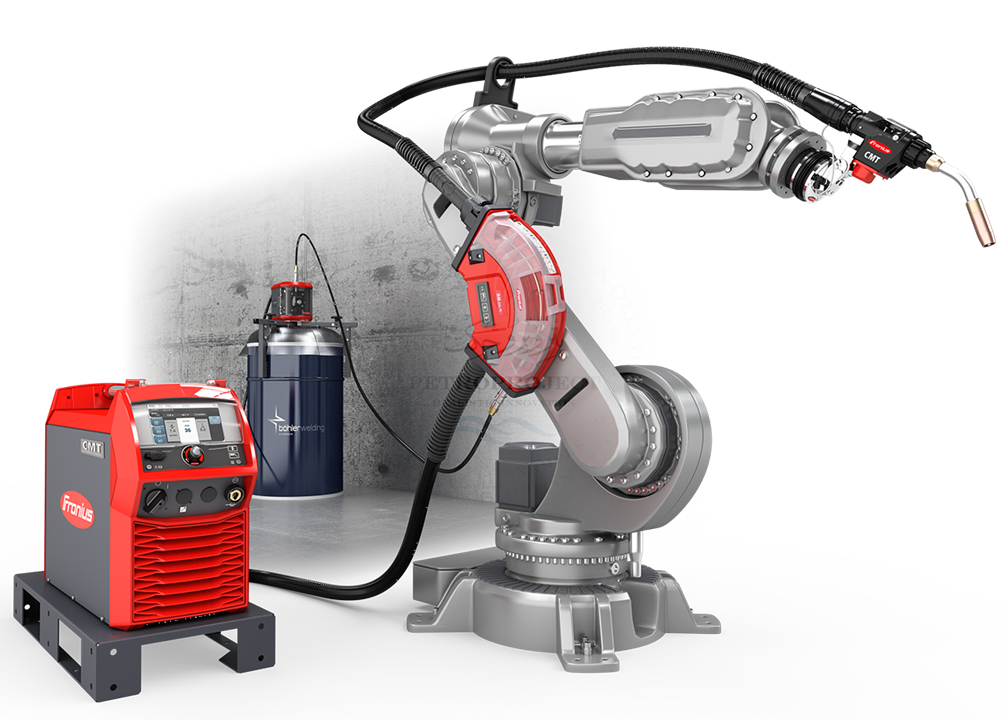

| Petroproject Welding Machines

Welders are one of the essential tools in the manufacturing industry for joining metals and other materials. So many welding processes could be needed, and no single welding machine fits them all. As a result, Petroproject at least ten different welder types are available to handle most welding projects. Each machine type has its unique features and capabilities with variations in characteristics.

Here is a look at the most popular welding machine types and some you might not be as familiar with, along with their uses: Shielded Metal Arc Welding Machine [Stick] MIG Welding Machine TIG Welding Machine Flux-Cored Arc Welding Machine Energy Beam Welding Machine Plasma Arc Welding Machine Submerged Arc Welding Machine Atomic Hydrogen Welding Machine Oxyacetylene Gas Welding Machine Multipurpose Welding Machines

|

Tube - to - Tube Sheet Orbital Welding Machine… For Heat ExchangerThe Petroproject series orbital tube to tube-sheet weld head is designed for fabrication of various heat exchangers and boiler industry. It can be used for recessed, projected and flush tubing with or without wire feed. Tungsten Inert Gas [TIG] / Gas Tungsten Arc Welding [GTAW] that efficiently welds tube to tube-sheet with the highest precision and accuracy while consistently producing high quality welds.

Features Of Ots Tube to Tube Sheet Orbital Welding Machine With/without wire feeding TIG DC/pulse welding Continuous rotation of the weld head with no cable twist Suitable for Tungsten electrodes 1/16 up to 1/8 Expandable pneumatic mandrel/ mechanism clamp for easy positioning Welding Torch Angle 0°- 30° or any angle Easily connects to the balancer Compatible with manipulator – useful within the heat exchange industry Material types – carbon and stainless steel, and other alloys For flush tube, recessed and projected [not over 5mm] tube ends. |  |

| Petroproject Inspection and calibration Devices

Test & measurement instruments and systems – from the audio to the millimeter wave range Petroproject has a wide range of electronic test and measurement equipment provided by largest manufacturers. All devices are following standards in research, inspection, calibration development, production and service. Measurement tools such as: a dimension, depth burn-in, evaluation limits and standard-compliant inspection report are included as standard in the proven and user-friendly.

Petroproject Inspection and calibration Devices includes but not limited to: Visual inspection tools Ultrasonic thickness Measurement device Ultrasonic Welding Measurement Device Vibration Detector and Control Device Lase-Gauge Alignment Device Electrical Inspection Package |

Petroproject workshop We Believe in modernity [Development Vs Improvement]