| Detergent Liquid IndustryPetroproject EPC Projects Integrated Industrial System |

Brief introduction of Petroproject production system

Petroproject offers an integrated system which cover more than 150 products starting from raw materials preparation, metering, mixing, homogenizing and packaging.

Petroproject system is matching to detergent Liquid and Cosmetics industries.

| Raw materials and utilitiesThe main raw materials used in oil and soap industry are seeds, such as cottonseeds, soybeans, sunflowers, or fruits such as olives and palm. Also, palm stearin, palm oil, animal fats, and calcium silicate are used for soap production. The chemicals used are caustic soda [NaOH], sodium silicate, sulfuric acid, hexane, fuller earth [bleaching agent], perfumes, coloring materials, coagulating agent (alum), molasses or vinasse for animal fodder, citric acid, antioxidant and phosphoric acid, and sodium chloride.

In synthetic detergents manufacturing the following chemicals are used: Long chain paraffins [C10 – C18] such as kerosene or linear alkyl benzene, sulfuric acid (commercial or oleum), caustic soda, sodium tri polyphosphate, fatty alcohols, sulfated fatty alcohols, sulfated acids and esters, alkyl aryl compounds, aliphatic poly hydric alcohol esters, fatty acids amides, chlorine gas, catalysts such as iodine or aluminum chloride. Sodium silicate, sodium carboxy cellulose, fluorescent, dyes, enzymes are used as additives. |

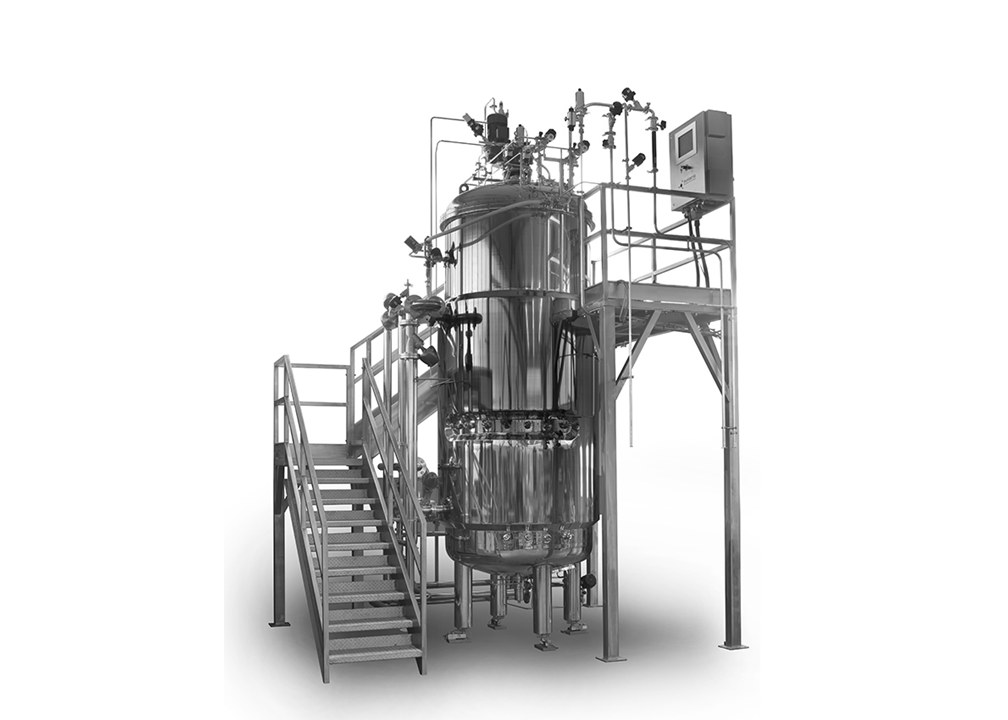

Petroproject Vacuum Homogenizer MixerPetroproject vacuum homogenizer mixer, also called vacuum homogenizer machine, It’s the most advanced homogenizer machine, is designed in accordance with European specification and is especially suitable for making big batches of liquid detergent, chemical industries and emulsions with large quantity of powders.

The Feature: Working capacity from 50L to 10000L. Suitable for products and emulsion of 10,000~100,000cps viscosity. Perfect particle size of 2 micrometers and evenly distributed. External emulsifying and homogenizing by vertical type inline homogenizer with pipes. Shorter batch time compared with other vacuum emulsifying mixer. Complete process of mixing, dispersing, emulsifying, homogenizing, vacuuming, heating and cooling in one unit. Double temperature probes and controllers for electrical heating in main vacuum homogenizer machines. Cooling system for mechanic seal inside the homogenizer for longer homogenizing time. The homogenizer also works as a transfer pump for discharging finished products. Contra mixing system of fixed impellers with holes and wall scraper. Outer anchor agitator has pipe design for enhanced mixing and good appearance. Variable speed for homogenizer and agitator. Oil hydraulic lifting system for easy cleaning and maintenance. Double jackets for heating and cooling.

General Application Cosmetics & Toiletries: cream, lotion, wax, mascara, gel, toothpaste. Pharmaceuticals: ointment, dental composite, syrup, injection. Food: mayonnaise, dressing, jam, butter, margarine, wasabi. Chemicals: polyester, synthetic fiber, shoe cream.

Mixer Options Movable-Hydraulic / Fixed cover with bolts or welding to save budget. Different slow mixing part designs are available. Frame type slow agitator for oil pre-mixer. Extra openings on the vertical type of inline homogenizer for adding hot and cold ingredients and powders. Flow meter automation for feeding liquid oil and water. Pressure vessel design for different steam pressure. Different power supplies are acceptable. PLC for automation of mixing, dispersing, emulsifying, homogenizing, vacuum, transferring, heating and cooling etc; |  |

Automatic Filling Machine | Automatic Capping Machine | Automatic Labeling Machine | Automatic Cartooning System Machines |

Complete and independent machine, designed for the execution of filling processes at adjustable speed with a wide range of products gel, liquids, creams. Machine equipped with hopper loading system, automatic equipped with minimum and maximum level with transfer pump.

Fully automatic filler equipped with bottle inlet and outlet sensors, loading arm movement management with pneumatic motors, head immersion time management in case of foamy products

Dosing group managed by magnetic pump Adjustable operating air pressure Pneumatic motors which, thanks to the lower mechanical resistance, eliminate the formation of sparks and reduce the need for maintenance Cylinder filling chambers with Teflon piston EPDM gasket [Viton on request] Possibility of adjusting the filling speed according to the product Hopper with lid that can be opened for inspection or maintenance | Complete and independent machine, designed for the execution of capping processes at adjustable speed with a universal range of capping: Triggers, Dosers, Screw.

The machine can be equipped with a trigger loading system, dosers and automatic caps. Automatic capping machine equipped with bottle inlet and outlet sensors, cap screwing by no. 4 variable hardness rubber wheels [on request]

Capping unit adjustable in width and height according to the cap Air / electricity operation Adjustable operating air pressure Complete Screwing system | Complete and independent machine, designed for round bottles or other common cylindrical products. Such as cylindrical plastic bottles, glass bottles, metal bottles. It is mainly used for labeling round or round containers in food and beverage, and personal care products.

Equipment production efficiency: single shrink label feeding plate, microcomputer control, automatic detection, positioning, fast label change, labor-saving, accurate cutting position Suitable for all kinds of bottle. Touch screen user-friendly operation ... Sensors, servo motors, frequency converters and other well-known brands. Bottle type Round and square

| Complete and independent system, including three automatic machines starting from adjusting the bottles till producing final box with complete tapping.

The System Include Carton forming machine Bottle positioning inside cartons machine Machine for box closing] |

|  |  |  |

Design easy-to-use, convenient liquid detergent formats that require less water

Petroproject is at the forefront in meeting liquid detergent format needs with deep market understanding and extensive experience.

Our portfolio includes surfactants, conditioning polymers, solvents, antifoams and dispersants to help brand owners develop high-performing, sustainable, and differentiated liquid detergent and monodose products.

With bio-biased ingredients that work well in colder wash temperatures and use less water,

Petroproject helps clients to offer products that are safer.